Mercury’s LWPF is designed to provide improved performance across the full wavelength region form 1265 to 1625nm.

Mercury’s LWPF fully meets ITU-T G.652 and is available for use in loose tube cable, ribbon and other cable designs. Mercury use ultra-pure materials based on silica, so this optical fiber has excellent optical and mechanical performance.

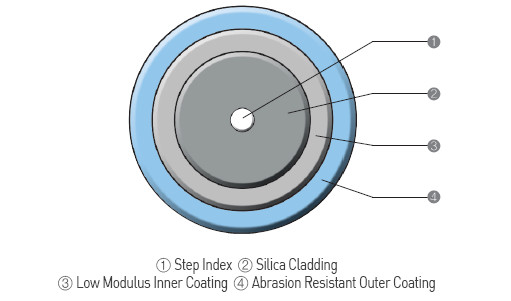

SMF (LWPF)

- Low 1383nm attenuation for full utilization from 1265 to 1625nm

- Fully compliant with (ITU-T G.652.D & G.657)

- Small allowable bending diameter

- Mechanically strippable coating for easy field application.

- Compatible with any commercial optical devices.

- Local area network systems

- Long haul telecommunication

- Closed circuit television system

- Process control systems

| Items | Specifications | |

| Attenuation | @1310nm | ≤ 0.34 dB/km |

| @1383nm | ≤ 0.31 dB/km* | |

| @1550nm | ≤ 0.21 dB/km | |

| @1625nm | ≤ 0.22 dB/km | |

| Dispersion | @1285nm~1330nm | ≤ 3.2 ps/nm.km |

| @1550nm | ≤ 18 ps/nm.km | |

| PMD | Individual Fiber | ≤ 0.20 ps/√km |

| Link Value | ≤ 0.10 ps/√km | |

| Zero Dispersion Wavelength | 1300~1320nm | |

| Zero Dispersion Slope | ≤ 0.092 ps/nm².km | |

| Cutoff Wavelength | Fiber | 1150~1330nm |

| Cable | ≤ 1260nm | |

* After hydrogen aging test based on IEC 60793-2-50

| Items | Specifications |

| Mode Field Diameter @1310nm | 9.2±0.4㎛ |

| Cladding Diameter | 125±0.9㎛ |

| Cladding Non-Circularity | ≤ 0.9% |

| Core/Clad Concentricity Error | ≤ 0.7㎛ |

| Coating Diameter | 245±10㎛ |

| Items | Specifications |

| Proof Test Level | ≥ 100kpsi (0.7GN/㎡) |

| Coating Strip Force | 1.3~8.9N (Nom. 3N) |

| Tensile Strength (Gauge 0.5m) | ≥ 550 kpsi (0.3.8GN/㎡) |

| Dynamic & Static Fatigue | ≥ 23 |

| Test Method | Test Condition | Induced loss @1310nm | Induced loss @1550nm |

| Temperature Dependence | -60℃~+85℃ | ≤ 0.05 dB/km | ≤ 0.05 dB/km |

| Temperature Humidity Cycling | -10℃~+85℃ / RH 95% | ≤ 0.05 dB/km | ≤ 0.05 dB/km |

| Characteristics | Typical Value | |

| Group Refractive Index | @1310nm | 1.467 |

| @1550nm | 1.468 | |

| Refractive Index Difference | 0.34% | |

| Zero Dispersion Wavelength | 1313nm | |

| Zero Dispersion Slope | 0.086 ps/㎚2.㎞ | |

| Dispersion at 1550nm | 16.5 ps/㎚.㎞ | |